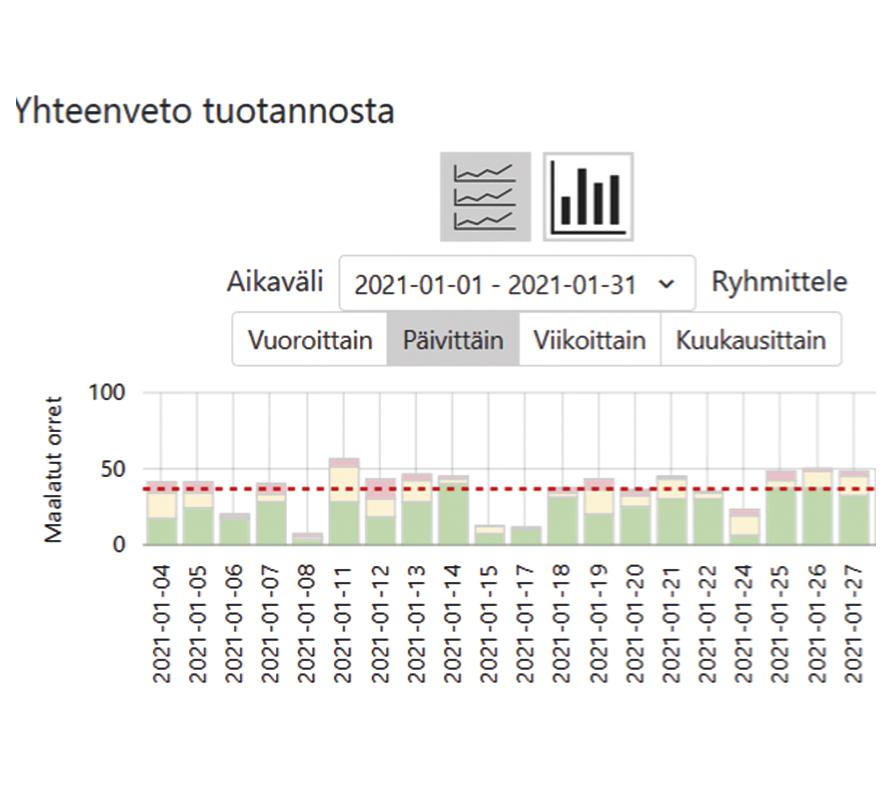

Painting line occupancy

The due time is improved by reducing unnecessary color changes and identifying organizational errors in the painting queue. The filling level is improved by the suspension technology and by monitoring the success of the suspension. Painting technology can be improved through equipment improvements and staff working methods.

In the Pekocare productivity system, the occupancy rate is documented and evaluated, after which the data is brought into an easily reportable visual format. Once visual data is available, productivity-enhancing optimization measures can be performed