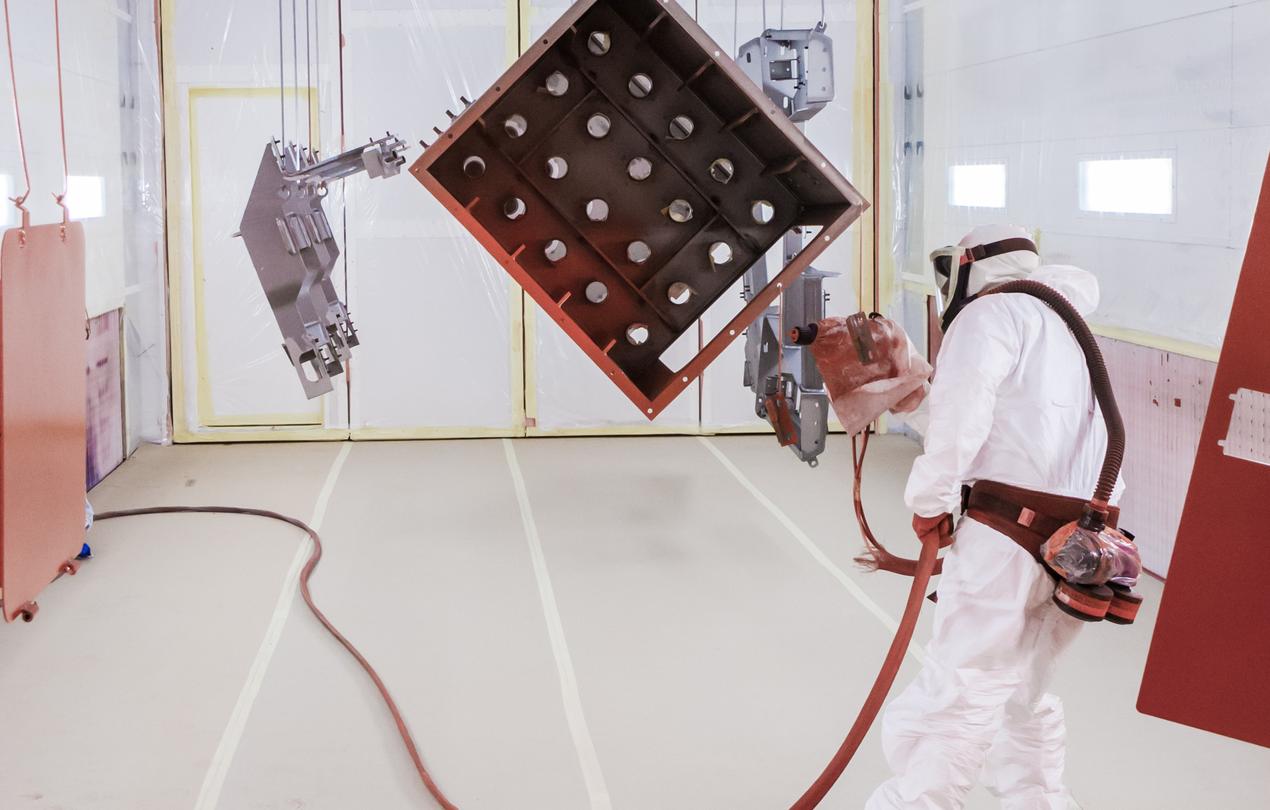

The most energy-efficient wet painting solutions on the market

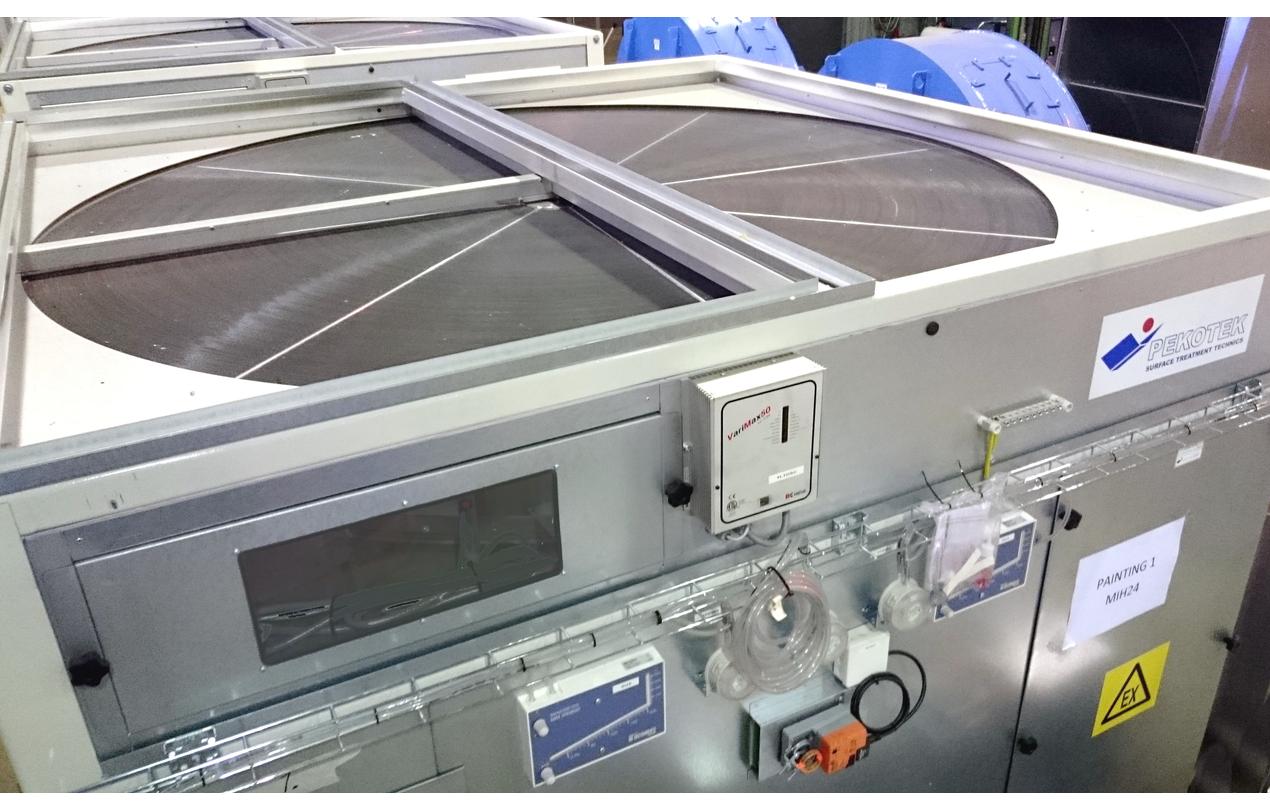

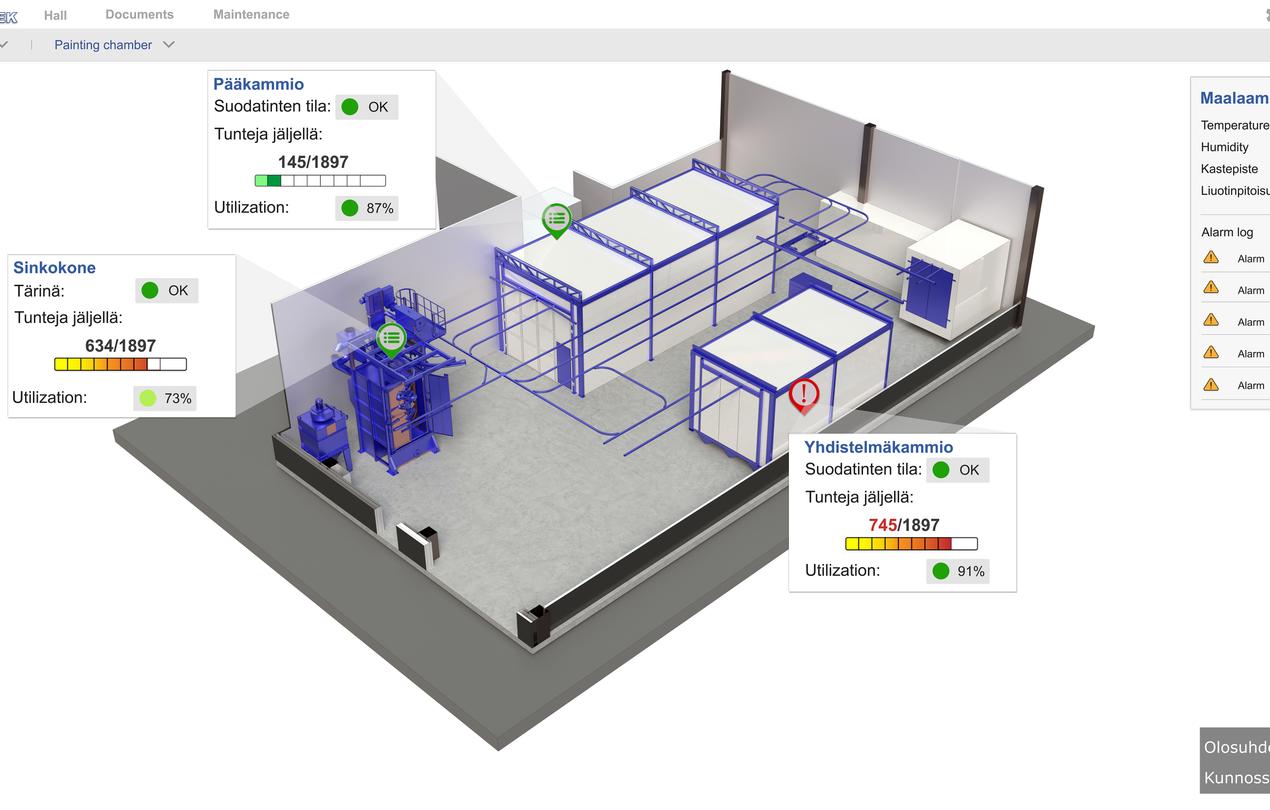

Our painting process is equipped with gas / humidity control as well as efficient heat recovery and low energy consumption. The equipment is reliable and low maintenance. All fans are equipped with frequency converters, so the vacuum balance and air volumes in the chambers can be adjusted automatically, taking into account the optimal energy consumption and conditions.

Automatic gas monitoring ensures clean and safe working conditions and adjusts the exhaust air according to the actual need, enabling efficient air recirculation.